The quality of secondary housing and most new buildings still leaves much to be desired. Uneven ceilings and walls are the least that homeowners face. One can write sad songs about the noise from neighbors or from the street, penetrating through cracks and walls, like through a sheet of paper. But demand always provokes supply - a multifunctional wallpaper substrate has appeared on the building materials market, the installation of which, according to the manufacturers, immediately solves these problems.

The construction axiom - the surface must be carefully prepared before finishing - is not always achievable in practice. The obstacle is either the lack of money, or the reluctance to get involved in dirty work, but be that as it may, pasting over an unfinished wall is wasted work. Any defect, such as a permanent stain or crack, can appear under the wallpaper, especially if it is thin, and completely distort it appearance.

Roll of insulation backing

This is where wallpaper backing comes in handy - reviews indicate that it actually helps to slightly even out the surface and its color. There are several varieties of such substrates, and they all have their own advantages and disadvantages:

- paper - a base made of thick paper is especially useful in cases where it is impossible to remove the old finish, but it is fragile and does not hide obvious surface flaws;

- non-woven wallpaper - similar to regular non-woven wallpaper, they have the same advantages (durability and ease of gluing), but their disadvantages include the high cost of double finishing;

- cork - not decorative cork is used as a repair base, but technical cork, so it is cheaper than the finishing material, absorbs sounds well, but requires installation skills and the purchase of special types of glue;

- polyethylene - they are foamed polyethylene, on which two layers of paper are applied on both sides, in addition to masking surface imperfections, they serve as heat and sound insulation.

Since the idea of installing thin soundproofing of walls in an apartment under wallpaper seems tempting to many, it is worth considering in more detail the pros and cons using the example of the most popular building materials and reviews about them.

Rolled backing 5 mm thick

Review of popular heat and sound insulating substrates

The idea of using polyethylene foam as a cheap thermal insulation pad is not new: polyethylene is the most common plastic in the world, which, when foamed, effectively prevents heat transfer between two spaces. Naturally, this property has not been ignored by manufacturers of thermal insulation, and in construction stores you can now often find rolled materials such as EcoHeat and Penolon. What are their characteristics?

Properties and scope of EcoHeat

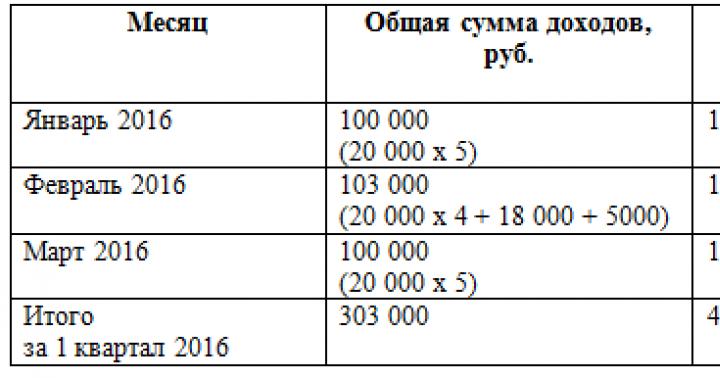

“EcoHit” is a soundproof wallpaper for apartment walls, produced in Russia (Izhevsk Plastics Plant LLC), made from physically cross-linked polyethylene foam Isolon500 and paper welded on both sides. A sandwich of paper layers ensures adhesion of the substrate to the wall and subsequent decorative finishing. The manufacturer offers two sizes finished products:

- Ecoheat wallpaper backing 3 mm thick, roll length 14 m and width 0.75 m;

- Ecoheat 5 mm thick – with a roll length of 14 m and a width of 0.5 m.

Leveling underlays of other formats or backed with foil are intended for laying under parquet, laminated boards or under a “warm floor” system. The main purpose of sticking rough wallpaper for walls is a soundproofing and insulating effect, which is ensured due to the physical and mechanical properties of polyethylene foam:

- almost zero vapor permeability;

- low (within 0.031–0.034 W/m °K) thermal conductivity coefficient;

- high noise reduction rate (specific value not specified).

Properties of foamed polyethylene

As additional advantages of using the material, the manufacturer points to:

- hygienic safety and environmental friendliness - polyethylene is indeed non-toxic and does not cause allergies;

- simplicity and low cost of installation - “EcoHit” can be glued using a special glue for heavy wallpaper, or using ordinary construction PVA;

- versatility - the product fits under all types of wallpaper and is suitable for improving the heat, noise and vapor insulation of apartments, private houses and administrative buildings, both in facilities under construction and in renovations.

Externally, EcoHeat is a lightweight, elastic, roll material white. Its cost varies depending on the place of delivery and the volume of the order from 1100 to 1950 rubles per roll.

Penolon - characteristics and purpose

A manufacturer of soundproofing wallpaper called “Penolon” offers a chemically cross-linked polymer that has the following properties:

- hygiene, elasticity and lightness;

- resistance to aggressive environments - acid, alkali, alcohol, gasoline;

- minimal residual deformation;

- low vapor permeability and thermal conductivity.

Scope of application of "Penolon"

Purposes of application:

- leveling wall surfaces;

- increasing the level of noise reduction;

- elimination of cold radiation from walls;

- easier gluing finishing;

- solution to the problem of crying walls.

In stores you can also see the Penofol building material - this is an analogue of the Penolon wallpaper backing, reviews of which indicate that they are the same material. You can purchase a standard roll for about 990 rubles.

Products from other brands

The range of soundproofing wallpaper underlays is not limited to two brands. Other brands produce similar products. To determine the differences, it is worth understanding the classification of polyethylene foam as a whole. So, there are three classes of this polymer:

- gas foam not cross-linked (“Teploflex”, “Vilaterm”, “Porilex”, etc.);

- chemically cross-linked (“Penolon”, PoliFoam);

- physically stitched (EtaFoum, HitFoum).

Non-crosslinked polyethylene foam is the most cheap material of the whole three, since it is manufactured using the simplest technology. Its strength and heat-insulating properties are 25% worse than those of polyethylenes of a higher class. Therefore, you should not be surprised by negative reviews - wallpaper under wallpaper made of non-cross-linked gas foam polyethylene does not give a clear result and does not last long.

Cross-linked polyethylene differs from non-cross-linked closed-cell polyethylene

Physically and chemically cross-linked materials, despite different production technologies, are almost identical in properties. When deciding which brand to give preference to, it is recommended to pay attention to the visible characteristics of the roll: color (should be uniformly white or light gray), strength of paper attachment to the base, absence of odor, elasticity (correctly, if after pressing with a finger the surface quickly restores its shape).

Advertising VS customer reviews

Manufacturing companies confidently declare that the sound and heat insulating effect of installing polyethylene foam wall insulation under wallpaper in an apartment is comparable to the effect of laying bricks 125 mm thick (“half a brick”). Whether this is actually true can be found out by studying reviews from real customers:

Olga L., Saratov:

“My husband and I were thinking about insulating an apartment in a cold panel house. It was decided to put a noise-insulating wallpaper underlay on all external walls from the inside. The gluing process was expectedly simple, but speed was required - the reaction time of the glue was only 10 minutes (they used repair and installation acrylic composition). We are not 100% happy with the result, as we had to replace it paper wallpaper non-woven ones (strange gaps formed between the paper ones). The rooms became a little warmer.”

The material can be cut well with a construction knife

Maria V., Moscow region, Ivanovo:

“I’ll share my impressions of the method of soundproofing in the apartment: I glued a special backing under the wallpaper, the inscription on which promised a significant reduction in noise levels. I bought and carried the material home myself, fortunately the rolls have a comfortable handle and they weigh very little. I read the reviews and decided to glue the insulation onto PVA emulsion, strengthening the joints with masking tape - this is so that they do not separate. I attached colored wallpaper to the top using regular wallpaper glue. Now about the result: the substrate lived up to expectations - the neighbor’s stomping behind the wall became quieter.”

Oleg K., Ufa:

“In general, I recommend products like EcoHit or Penolon - their sound insulation is minimal, but they retain heat and smooth out the walls. I didn’t want to insulate my Khrushchev-era box using specialized methods and ended up gluing a polyethylene foam backing under the wallpaper. The price and material consumption were pleasantly pleasing: for a room of 17.2 sq. m. it took 2 rolls. After installation, the room became more pleasant to be in, although the noise from the entrance (one wall borders it) is still audible.”

Proper installation of wallpaper underlay

As can be seen from the reviews, the effectiveness of heat and sound insulation of the wall in an apartment under the wallpaper largely depends on whether the backing was glued correctly. This is echoed by the instructions that manufacturers usually include with each roll. The installation algorithm for them consists of several steps:

- Cleaning the wall of the old coating and removing loose plaster.

- Repairing deep potholes and cracks.

- Marking and cutting rolls into pieces of the required length.

- Applying wallpaper glue to the base surface and backing.

- Gluing the substrate to the wall strictly vertically.

- The base is completely dry within 72 hours.

- Gluing the cladding according to the instructions for it.

Deep cracks and chips must be repaired

In addition to the sequence of actions, the microclimate conditions that must be maintained during the process are also specified: air temperature not lower than 10 ° C, humidity not more than 70% and maximum absence of drafts. If you adhere to these rules, the manufacturer guarantees the service life of the insulation for 20-40 years, and the old wallpaper can be removed with ordinary water and new ones can be pasted onto the same substrate.

Many reviews complain that when the wallpaper dries, the joints separate and form unattractive seams. To prevent such an incident and alleviate installation work, experienced craftsmen offer their own “folk” instructions:

- to stabilize the canvases and prevent the appearance of cold bridges, the joints can be taped with paper tape;

- when gluing wallpaper over a backing, it is better not to allow the joints of both materials to overlap each other;

- Do not wrap the backing sheets at the corners, but install the cut close to them;

- at the slightest suspicion of a fungus, appropriate treatment must be carried out.

It's time to draw final conclusions: it will not be possible to completely protect your home from noise pollution with just a thin substrate. For this purpose, acoustic engineers develop soundproofing structures with a thickness of at least 40–50 mm. On the other hand, few buyers are willing to sacrifice the space that full sound insulation takes away for the sake of silence.

As for heat retention, rough wallpaper copes well with this function - at least it stops the cold from blowing from the walls. And finally, the last argument in favor of universal substrates is the quick and problem-free leveling of walls that, however, have minor defects. So, if you want to get a predictable and long-term result after finishing the walls, it is still better to install a universal backing for wallpaper.

Modern new buildings and secondary housing cannot always boast of high quality. The smallest problems that owners have to deal with are uneven walls and ceilings. Noise from the street, loud neighbors - the walls, like a sheet of paper, let any sound through. However, every problem can be solved, and therefore the modern market building materials can offer a special wallpaper backing that will solve these and many problems.

What is it?

The underlay is a special intermediate layer that serves to level the wall and also enhances the adhesion between the wallpaper and the plaster. There are ordinary, standard substrates and materials with specific properties, such as vibration damping and noise suppression.

Substrates are made from synthetic materials and natural raw materials. Synthetics are often represented by a layer of polyethylene and paper fused with it.

Natural products are most often made from cork oak bark and other materials that have a pronounced property of absorbing and dampening vibration.

Peculiarities

Modern substrates are made from environmentally friendly raw materials, so they allow finishing work both inside residential premises and in public places. These materials can compensate for base defects, as well as mask and strengthen cracks.

Specific features such as sound insulation, thermal insulation and noise insulation abilities, will help create the necessary comfort and coziness in the house, as well as protect the work area. And the finishing coat will be smooth, even and will last much longer than without the use of a substrate.

The following positive points should also be noted:

- The final coating has a smooth, bubble-free surface. The backing absorbs some of the glue, so it is distributed evenly over the entire wall.

- The gluing process itself becomes much simpler and more practical. The insulation, due to its structure, helps to firmly fix the fabric in the seam area and corners.

- A long service life of the wall decoration is achieved. The increased degree of adhesion allows the base and coating to be firmly grasped.

- A substrate that has good breathability will prevent the formation of mold on the wallpaper.

- Significant savings in time, materials, effort and financial resources.

Substrates may have different characteristics, but one type can be used for different types wallpaper

Of course, an intermediate layer between the topcoat and the plaster is not necessary, but it is advisable.

Popular materials

There are several types of substrates, depending on the raw materials:

- Paper. Thick paper allows you to correct the wall if it is not possible to dismantle the old, damaged plaster.

- Non-woven fabric. The base is similar to ordinary non-woven wallpaper. They are durable, but lightweight and have good sound insulation characteristics. However, they are quite expensive materials.

- Cork. Inexpensive technical jam, which is why the resulting material is distinguished by its budget. The substrate has excellent heat and sound insulation characteristics, it levels the walls well, but requires installation skills and a special adhesive composition.

- Polyethylene. It is made of foamed polyethylene. It hides wall defects well, has such characteristics as sound insulation, and retains heat in the house.

Expanded polystyrene or its more common name is polystyrene foam. The simplest thermal insulation material known to a wide range of consumers. Different low cost and good thermal insulation properties, therefore has a wide scope of application. With its help, walls, floors, ceilings, and even house facades are insulated.

Polystyrene foam is a good and proven option for insulating residential and industrial premises.

However, it is absolutely impractical for wallpapering. This conclusion can be made based on the following features of expanded polystyrene:

- Polystyrene foam has a loose structure, its surface is very fragile and not rigid enough for wallpaper. In other words, if someone suddenly presses on the wall or leans against it, a dent will form in this place and the wallpaper will tear. Also, during use, abscesses may form on the canvas.

- In stores, foam plastic is sold in the form of slabs, therefore, in order to ensure high-quality thermal insulation, the foam layer must be at least 5 cm. The main problem is the seams - they protrude too much above the wall surface and will be noticeable under the wallpaper.

- When carrying out cosmetic repairs, it will be possible to dismantle the old wallpaper only together with the insulation. This is not very convenient and adds extra work, since you will have to glue not only wallpaper, but also a new backing.

- And the last, most important factor is fire safety. To comply with all the rules, you must first cover the foam and trim it with non-flammable material, which is also impractical.

If, nevertheless, the choice settled on polystyrene foam, then to give a rigid base for the wallpaper You can use three additional coatings:

- Cover it with plasterboard.

- Cover with special plaster with reinforcing properties.

- It is necessary to use a fiberglass-based plaster mesh.

Insulation can be made from various materials. However, the most common is polyphome. It is made of foamed polyethylene. Its thickness can vary from 4 to 8 mm. Polyfoam is an environmentally friendly material. There is a paper lining on both sides. You can purchase polyform in the form of rolls in a specialized store. Roll parameters:

- Length – 14 m.

- Width – 0.5 m.

- Thickness – 5 mm.

- Density – 30 kg/cube m.

Penolon is a polymer and is chemically cross-linked. It is characterized by elasticity, light weight and hygiene. The material is quite resistant to exposure to aggressive environments such as acid, alkali, alcohol and gasoline. It is not subject to deformation, and also has a low coefficient of vapor permeability and heat conductivity. Areas of application of Penolon:

- Levels walls.

- Suppresses noise and vibration.

- Reduces the spread of cold from walls.

- Facilitates the work of pasting walls.

- Eliminates the "crying walls" phenomenon

Foamed polyethylenes also include polyform and polyphon, which have similar characteristics to the above materials. Even if the layer is thin.

Penohome is universal material having different densities. It is a European bloc. Has excellent sound insulation properties. Copes well with high humidity and helps insulate the room.

The cork substrate has high thermal and sound insulation properties. Significantly increases the degree of adhesion of the finishing coating and the base. In addition, the material is made from natural raw materials and is an ecological, natural and safe product for health. Technical features of the material:

- Thermal conductivity coefficient – 0.04 W/m2.

- Material density – 100-130 kg/m.

- Belong to a material of normal flammability (class - G3).

- Weight – 200 kg/m3.

Non-woven backing is also popular. Its main distinguishing feature is good steam permeability.

This provides excellent ventilation of the walls and rooms themselves. This material is also very elastic, so it easily masks non-critical defects in the base and is not very expensive. Rolled interlining has the following characteristics: length – 10-12 m, width – 0.6-1 m. The canvas can be glued vertically and horizontally.

Installation

Before finishing the walls with a finishing coating, you must first prepare them. This statement has long been an axiom. However, some owners for some reason do not want to prepare the walls, but you need to understand that gluing wallpaper literally onto bare surfaces is a waste of money and effort.

Installation of insulation does not seem to be a complicated process and takes place in several main stages. In most cases, there is no need to call a professional.

First you need to prepare the working surface itself (that is, the wall). It is necessary to dismantle the old canvas, loose plaster, paint and remove dirt. After this, you need to putty the walls, level out all the unevenness and small depressions. We cover the plaster with a deep penetration primer so that it becomes stronger and does not crumble. It is necessary to wait until the primer completely dry. You will have to wait about 24 hours. Only after this time can installation begin.

Now you need to measure the wall and cut the insulation into pieces of the required length. Let's start gluing. You will need either special adhesives (cork insulation) or just universal glue. Simply put, the glue must be chosen depending on the material taken. If there is a high level of humidity in the room, then you can use a composition for baguettes or liquid nails. They are quite expensive, but will not allow the lining to move away from the wall during strong temperature fluctuations. The most optimal values air temperature and humidity + 10 degrees, 70% humidity.

Using a roller, distribute the adhesive composition over the substrate and wall. We wait about 5 minutes, fix it on the base, smooth it with a rubber spatula. We do not allow drafts to occur at the time of gluing. To prevent divergence or bulging, glue the joints with wide masking tape. If you use something other than wallpaper glue, install it according to the instructions on the package. We wait for the glue to dry for 3 days.

While the composition dries, you need to ensure good ventilation of the room.

When choosing polymer insulation, you should know that according to the manufacturing method they are divided into:

- Non-crosslinked gas foam.

- Cross-linked: chemically and physically.

The simplest is uncrosslinked polyethylene. Its manufacturing technology is the simplest. The strength and thermal insulation properties of this material are 1/4 less and worse than the others.

Both chemically and physically cross-linked polyethylene are similar in their properties, therefore, when buying insulation, you need to focus on:

- Color of the material (uniform, white or light gray).

- How tightly the paper is attached to the base.

- Presence of odor (normally there should be no odor).

- Elasticity (the surface quickly recovers after finger pressure).

- Structure.

- Edge decoration.

- Durability and certificate availability.

When choosing a substrate, it is worth considering that Their main differences from each other are thickness and density. Cork material is denser, so it does not require thorough leveling of the walls before installation. Polyfom allows you not to thoroughly putty the walls. And non-woven fabric, which is a very durable material, will protect the wallpaper from tearing and the walls from cracking.

Some tips for laying the material:

- The joints must be treated with wide masking tape to stabilize the canvas and prevent the formation of hills on the seams.

- It is impossible for the seam of the wallpaper to coincide with the seam of the insulation.

- If there is a suspicion of the presence of a fungus, the necessary antiseptic measures are urgently taken.

These tips will help maintain the integrity of the wallpaper and prevent the seams from coming apart. It is better to use a primer that contains antiseptic substances. This is necessary to prevent the proliferation of various microorganisms. The finished surface should be dry and smooth.

There are many ways to make your home warmer and your stay much more comfortable. The first, and most effective, is wall insulation. Many technologies and materials will help with this. For example, wallpaper backing, which is becoming increasingly popular among residents of apartment buildings and private buildings. What is it, why is it needed and what materials is it made of?

Basic functions of wallpaper backing

Wallpaper backings from different manufacturers may differ in the presence of specific additional characteristics. But they all perform a number of important functions.

- Provide additional thermal insulation for walls. Let's be clear right away - the wallpaper backing cannot act as the main insulating material for outer wall. However, it is perfect for increasing heat saving efficiency, being important element insulating and insulating system.

- Helps create soundproofing of the room. The substrate is well suited for use on panel walls, which are not without reason called “paper” due to the low quality of sound insulation. Using a backing when covering such walls with wallpaper will help add not only warmth, but also peace to your home.

- The material provides waterproofing of the wall and wallpaper. Now no temperature changes or external dampness threaten the brand new wallpaper. The substrate does not absorb moisture and is not affected by dampness due to the fact that the dew point is shifted deeper from the wall surface. By the way, fungus does not form on the substrate either.

- The use of this finishing material allows you to avoid problems with wall unevenness. The substrate itself has a homogeneous, even structure, so gluing wallpaper on it is a pleasure. This eliminates the need to perfectly “smooth” the wall. But when using many types of wallpaper, this cannot be avoided. So the backing will help save money and time on finishing putty, while providing a perfectly flat surface for gluing wallpaper.

- As a rule, it is easy to apply the backing yourself. Most of the options sold on our market are reusable, that is, they can be wallpapered several times. At the same time, the material continues to maintain its performance qualities.

The beauty and attractive appearance of wallpaper is the merit of its outer, rolled up, outer side. But their performance and functionality largely depend on the substrate that is used and the material from which it is made. What types of substrates exist depending on the material they are made of?

- Foamed polyethylene backing. Trade names of this material may be different, for example, Izolon, Polyf, and so on. They are all made from the same material, which has high porosity, lightness, and low thermal conductivity (about 0.028 W). This indicator helps the substrate to effectively retain heat within the room. According to studies, one layer of such material, in terms of its thermal insulation qualities, successfully replaces a half-brick wall. Polyethylene insulator retains its performance properties in the temperature range from -60 to +90 degrees. Such wallpaper underlays have proven themselves very well for use on concrete walls, which quickly freeze and have rather poor thermal insulation properties. The use of polyethylene foam substrates helps to significantly increase the comfort of living in such a house. Insulation is sold in rolls. As for the cost, 1 roll of Polyfom (14 meters long and 0.5 meters wide) costs about 1,300 rubles. That is, square meter costs from 185 rubles. Ecohit substrate from Izolon, costs from 140 rubles per square meter. It is also available in 14-meter rolls.

- Cork backing for wallpaper has become very widespread due to the natural characteristics of the material from which it is made. To all the excellent qualities of the substrate, cork also adds environmental safety, good adhesion, and increased sound insulation of the room. It is not for nothing that recording studios are decorated with cork coverings for the purpose of effective sound insulation. It perfectly isolates the room from harsh sounds. Barking dogs, screaming, horns and car noise will not disturb you in a room isolated with cork. True, cork will not withstand structural noise. For example, impact construction machines, vibration of floors. But, to be fair, it must be said that no wallpaper underlay can save you from such noise. As for the thermal insulation properties of cork, it has a low thermal insulation coefficient, which is 0.032-0.04 W. This is comparable to the performance of polystyrene foam and even some types of extruded polystyrene foam. So cork backing- not only an effective sound insulator, but also an excellent insulation material. True, cork does not really like water and dampness. It is quite hygroscopic and does not have waterproofing properties. Therefore, if your walls often get damp, then it is better to use a wallpaper backing made of other materials. Cork - sheet material, its square meter will cost from 250 rubles.

- In the last few years, repair non-woven fabric has been increasingly used as a backing for wallpaper. This is a rolled non-woven material made from modified cellulose. It has a very valuable property - vapor permeability, due to which it is possible to natural ventilation walls, which helps remove dampness and moisture from the room. The non-woven fabric itself has good water-repellent properties, it is elastic, and has excellent adhesion to almost any surface. In addition, the non-woven backing for wallpaper allows you to further level the wall, well covering small irregularities and imperfections, thanks to the elasticity of the material. You can buy repair non-woven fabric at a price of 500 rubles per roll. The length of the roll is usually 10-12 meters, the width can vary from 0.6 to 1 meter. Non-woven backing for wallpaper is used in dry areas of the interior of a house or apartment; it is suitable for decorating children's rooms, rooms where people in poor health or elderly family members live.

Rigid materials, such as plasterboard or plywood, are sometimes used as a backing for wallpaper. This is especially justified if the walls are uneven or for some design reasons. Drywall is highly hygroscopic, like plywood, and therefore cannot insulate the room from dampness. In addition, the installation of such options requires additional space, since an air cushion must be left between them and the wall for air circulation. But the end result is good thermal insulation of the room and flat surface for gluing wallpaper.

It is quite easy to install wallpaper backing on walls, regardless of the material it is made from. Pasting algorithm different types the material will differ only in some nuances.

- First you need to prepare the wall. It must be cleared of old material, cracks and cracks must be plastered. If there is a layer of rough putty, it must be cleaned off.

- After this, you can prepare the material. Cut the rolled backing into pieces of the required length; simply remove the tile backing from the packaging.

- Glue for various types You will need different wallpaper substrates. For example, for repair non-woven wallpaper, you can purchase glue for non-woven wallpaper, and for a Polyfom-type substrate, glue designed for heavy wallpaper is quite suitable. By the way, do not forget that when installing a non-woven backing, the glue is applied not to the material, but to the wall.

- Glue sections or slabs of material using the joint-to-joint method, removing excess glue with a napkin. Start pasting from the window and move in a circle.

- After the pasting is completed, let the substrate dry for 24 hours. After this, you can start gluing wallpaper.

The backing for the wallpaper deserves attention as an effective insulating material that will provide additional protection for the home from cold, dampness and freezing of the walls, and will allow the wallpaper to maintain its original appearance longer.

Gone are the days when wallpaper was simply glued to the walls of apartments. Special finishing is currently being carried out interior walls to achieve longer service life of the coating, to make rooms protected from external sounds and noise. For this purpose, a special wallpaper backing is often used, which is an excellent means for leveling and.

In budget real estate, the walls have poor sound insulation, so it is recommended to use a substrate during renovation, on which the wallpaper will then be glued.

First of all, wall coverings are used to make the room warm and protected from external street noise. Also, wallpaper backings are an excellent material that helps to decorate walls and glue the material evenly. Other advantages of this technology include:

- High degree of strength, so the material will not tear quickly.

- The substrates are made from environmentally friendly materials.

- Prevents the formation of condensation and fungi.

- Creating a comfortable atmosphere in the room.

- Long operating time.

Thus, the range of applications for substrates is varied. The use of the material allows you to solve several problems that are typical for modern apartments and houses.

Types of substrates

The interior decoration of the rooms depends on the type of substrate selected. It is selected based on the following factors:

- The number of residents in an apartment or house.

- Location of housing.

- The influence of temperature, nature and weather conditions.

- Level of humidity and dampness.

There are several types of wallpaper substrates, which are most often used for interior decoration premises:

- Foamed polyethylene, which has a porous structure, lightness, and low thermal conductivity. This type of substrate is used to create warmth in the apartment. This material allows you to create sound insulation and retains its qualities at temperatures from +60 to +90. You can glue foamed polyethylene to concrete walls, reducing insulation costs. This substrate is sold in rolls.

- Cork backing is made from natural material, therefore it is safe, environmentally friendly, and has an excellent level of sound insulation and adhesion. It is recommended to use for rooms with thin walls, if the “effect” of street noise is constantly present in the house. This will protect the apartment or private house from barking dogs, voices of neighbors, car horns, sounds of repairs from neighboring apartments. Cork is wonderful thermal insulation material, but she is afraid of moisture and water. Therefore, this type of substrate is not recommended for regions or apartments with a humid climate.

- Non-woven backing is made from modified cellulose, which allows the material to remain resistant to steam. Thanks to this, the normal process of airing and ventilating the walls and removing moisture from living spaces occurs. Non-woven fabric is elastic, which allows it to be used on walls with uneven surfaces.

- Drywall is a hard type of substrate for wallpaper; it is used less often than other materials because it is susceptible to dampness and moisture. When using drywall, you must leave a gap between the wall and the material.

Acoustic wallpaper

On the market finishing materials You can also find a special type of wallpaper - acoustic. They are sold in rolls or slabs, so they are convenient to use for gluing ceilings and walls. Acoustic wallpaper has a high level of sound absorption. Surfaces perfectly reflect sound, resulting in a reverberation effect - sound creates an echo. To achieve this effect, the structure of acoustic materials is made from the following materials:

- Cellulose, i.e. paper. Sometimes it is replaced with non-woven fabric. These materials act as the basis of the wallpaper.

- The outer layer (top) is covered acrylic fabric or other fibrous materials consisting of fibers. Thanks to this, the fibers absorb sound.

There are acoustic wallpapers made of cork, finishing materials made from wood. In particular, from veneer, from bamboo, from grass. The thickness of the wallpaper is 3-4 mm, which depends on the material.

Soundproof acoustic wallpaper can be used to decorate the following rooms:

- Houses with low levels of sound insulation.

- Cinemas.

- Canteens.

- Bedrooms.

- Meeting rooms.

- Cabinets.

Advantages and Disadvantages

Acoustic wallpaper is used for wallpaper substrates, which allows you to create a high-quality level of noise protection in apartments and houses. Other advantages of the material include:

- The backing is very easy and simple to work with, which allows you to cut it into pieces without much effort, as well as stick it on the walls.

- When gluing, workers will not suffer from dust and odor.

- Environmental friendliness of the material.

- Long service life.

- Moisture resistance.

- Excellent fire characteristics.

- Impact resistance.

There is also a high level of practical use, since the wallpaper is relatively inexpensive. Anyone can purchase material to create a backing for wallpaper. No fastenings are used during repairs. It is also important that soundproof wallpaper does not eat up room space like other substrates.

The disadvantages of using acoustic wallpaper include the following factors:

- Due to its small thickness, the material is not always suitable for wall decoration - they can be translucent.

- It is not always possible to obtain a high level of noise protection for an apartment.

Selection criteria and manufacturers of acoustic wallpaper

In order to choose the right substrate designed to isolate the room from extraneous noise and sounds, you must adhere to the following criteria:

- Purpose.

- The area of the room or apartment.

- Prices per roll or package of wallpaper.

- Interior interior.

- The condition of the walls - do they need to be corrected, primed, or unevenness removed?

The main brands of acoustic wallpaper that can be found on the finishing materials market include:

- German brand AMF, which produces wallpaper in the form of slabs. They are made from clay, starch, water, perlin and mineral fiber. The surface can be different - smooth, perforated, structured.

- , Denmark. Also available in the form of slabs consisting of mineral wool, fiberglass, glue and covered with white acrylic paint.

- Rockfon, which are produced in Holland, France, Denmark. The panels are created on the basis of basalt fiber and stone wool, which allows for excellent sound absorption.

- Topakustik, Italy. The panels of this company are made from MDF, which has a density of 750 kg/m3.

- Mappysil, Italy. The products are made of polyurethane foam with different surfaces. Wallpapers from Mappysil have pyramidal, trapezoidal and wavy outer parts. Used in sound studios.

- , Germany - acoustic panels made from perforated plasterboard sound-absorbing materials.

Prices for soundproofing materials and acoustic wallpaper

- Sound-absorbing material, which is created from foam rubber panels, helps to create an excellent acoustic effect in the apartment, its price is 1,535 rubles / package.

- European volumetric wallpaper stickers with a 3D effect - the cost varies from 230 to 29.5 thousand per piece.

- Self-adhesive wallpaper, which is made of foam - the price is 361 rubles / piece.

- Acoustic panel that allows you to create excellent sound insulation - from 111 rubles / piece.

- Acoustic panels made of leather with 3 D effect - 21.1 thousand rubles/lot.

- Polyester acoustic wallpaper - from 1.4 thousand to 1,772 rubles / lot.

- Foam acoustic panel - from RUB 1,650.

- Decorative acoustic panels made of leather - from 22.1 thousand/lot.

- Self-adhesive 3D wallpaper “brick-like” - from 525 to 880 rubles/piece.

- PVC for gluing walls - from 153, 562 rubles/lot.

Soundproofing materials that are used to create comfort in an apartment differ in cost and the material from which they are made.

Before purchasing, you need to check with specialists for which room such wallpaper is suitable and whether it can be used as a backing.

Pasting process

The backing is very easy to use, so you won’t have to work hard with it while working. You only need to do the following:

- Completely clear the wall of wallpaper or other material.

- Large cracks and crevices are smoothed out by covering with plaster.

- The wall must be leveled so that there are no large differences due to unevenness. If such a need arises, the wall should be re-primed.

- The wall must be clean and dry.

- The roll of backing is cut into sheets of the length required for gluing. It is worth remembering that for non-woven wallpaper, you buy a special glue for non-woven wallpaper, which is applied only to the wall. For polyethylene foam and cork, glue must be applied to the substrate and the wall. After spreading the glue, wait 3 to 5 minutes for it to dry slightly. This will make it easier to place sheets of material in the desired place on the wall.

- The backing strips must be glued joint to joint, and then the seams must be reinforced with paper tape.

The substrate dries within 72 hours, after which you can start gluing the wallpaper. This should not be done before, otherwise they will not stick well and “wrinkle”.

It is better to wait a few days until the wallpaper backing is completely dry. To ensure that the wallpapering of the room does not suffer from the poor quality of the work performed, it is not recommended to carry out work when high temperature. The ideal temperature is +10, so repairs should be done either in spring or autumn. There should be no drafts in the room where they plan to work with the wallpaper backing.